Cone-Flo

In collaboration with Hyundai Motor Group

Cone-FLO is an aerodynamic indicator that visualizes airflow direction, separation, and speed in real time.

Inspired by the folding structure of a ginkgo leaf, it was developed for the Hyundai x RISD Collaborative Regeneration Studio.

The system provides immediate, energy-efficient data without relying on costly computational fluid dynamics.

Time, Money, and Energy

Computational Fluid Dynamics, specifically for testing on cars, can cost between $600 and $2,900 per run, according to Airshaper Online Aerodynamics software.

In addition to that, these simulations can take up to 24hrs and use excessive amounts of energy.

This project aimed to develop an energy efficient way to study a vehicle's aerodynamics with instant results.

How might we…

test the Aerodynamics of a car without software?

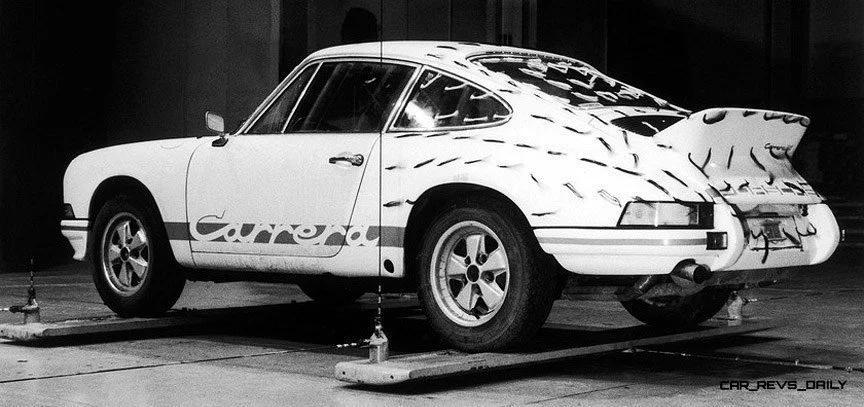

Existing solutions: Tufting.

Tufting a car includes taping pieces of wool to the surface of the car to help visualize direction of airflow and areas of separated flow.

Tufting a car falls short as it cannot record areas of changing airflow magnitude (which areas are faster).

Design Aim

Design a device that picks up where tufting falls short—an indicator that visualizes airflow direction, separation, speed.

How does nature…

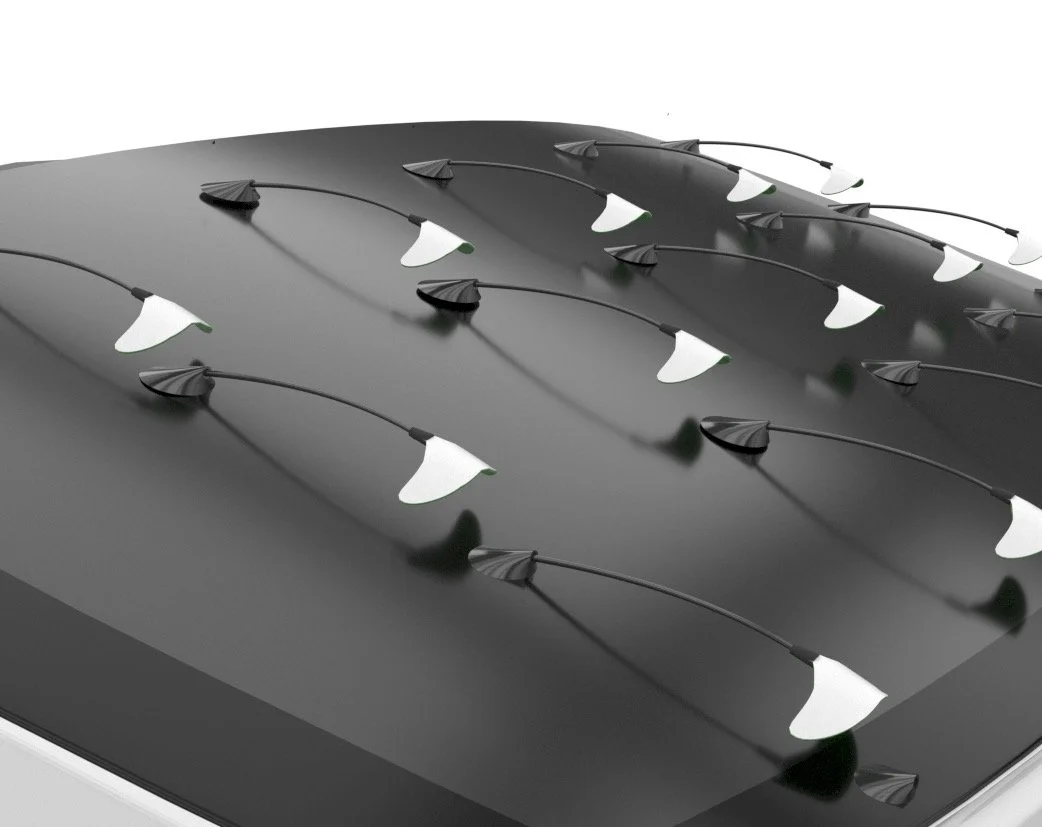

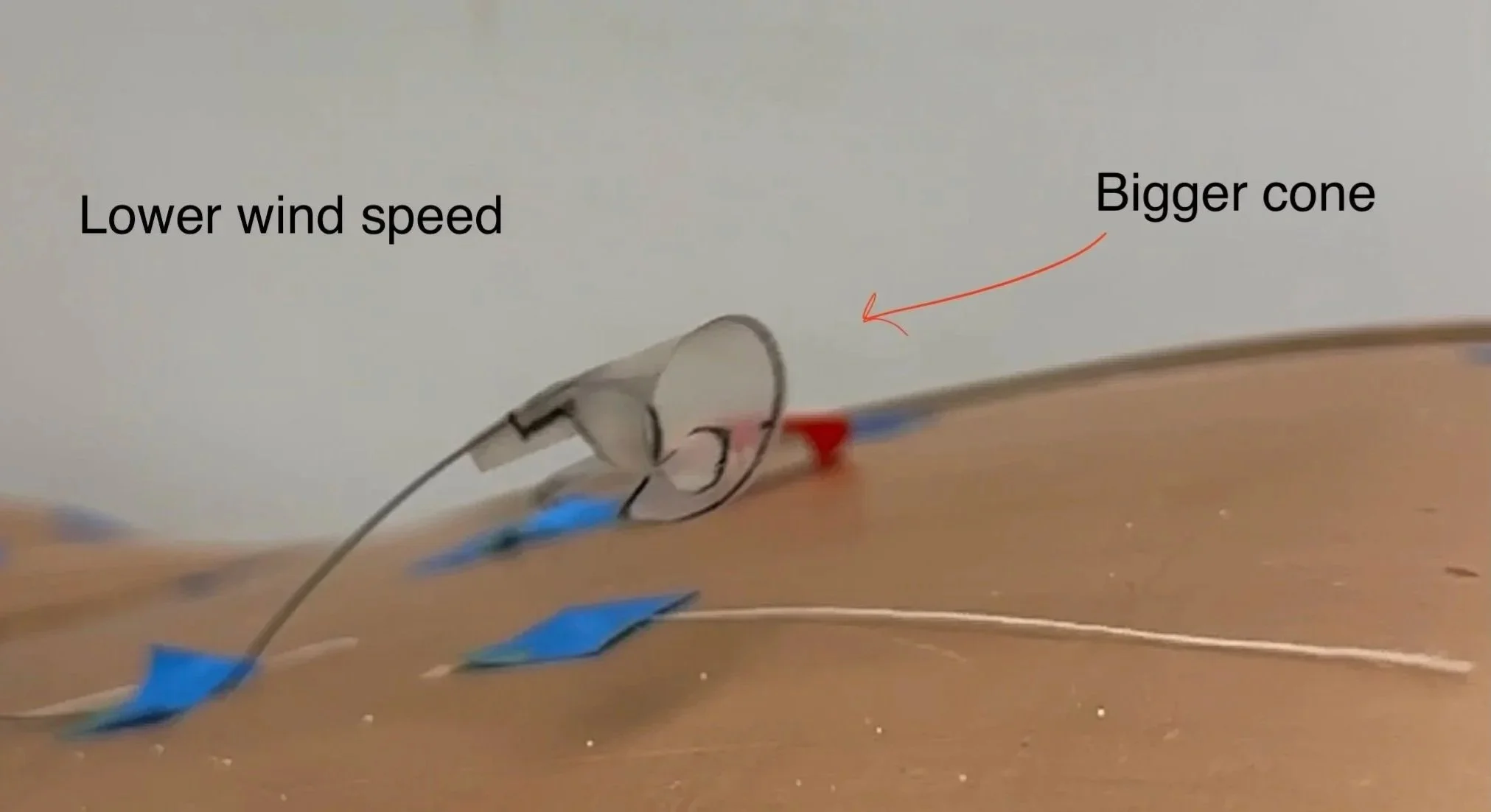

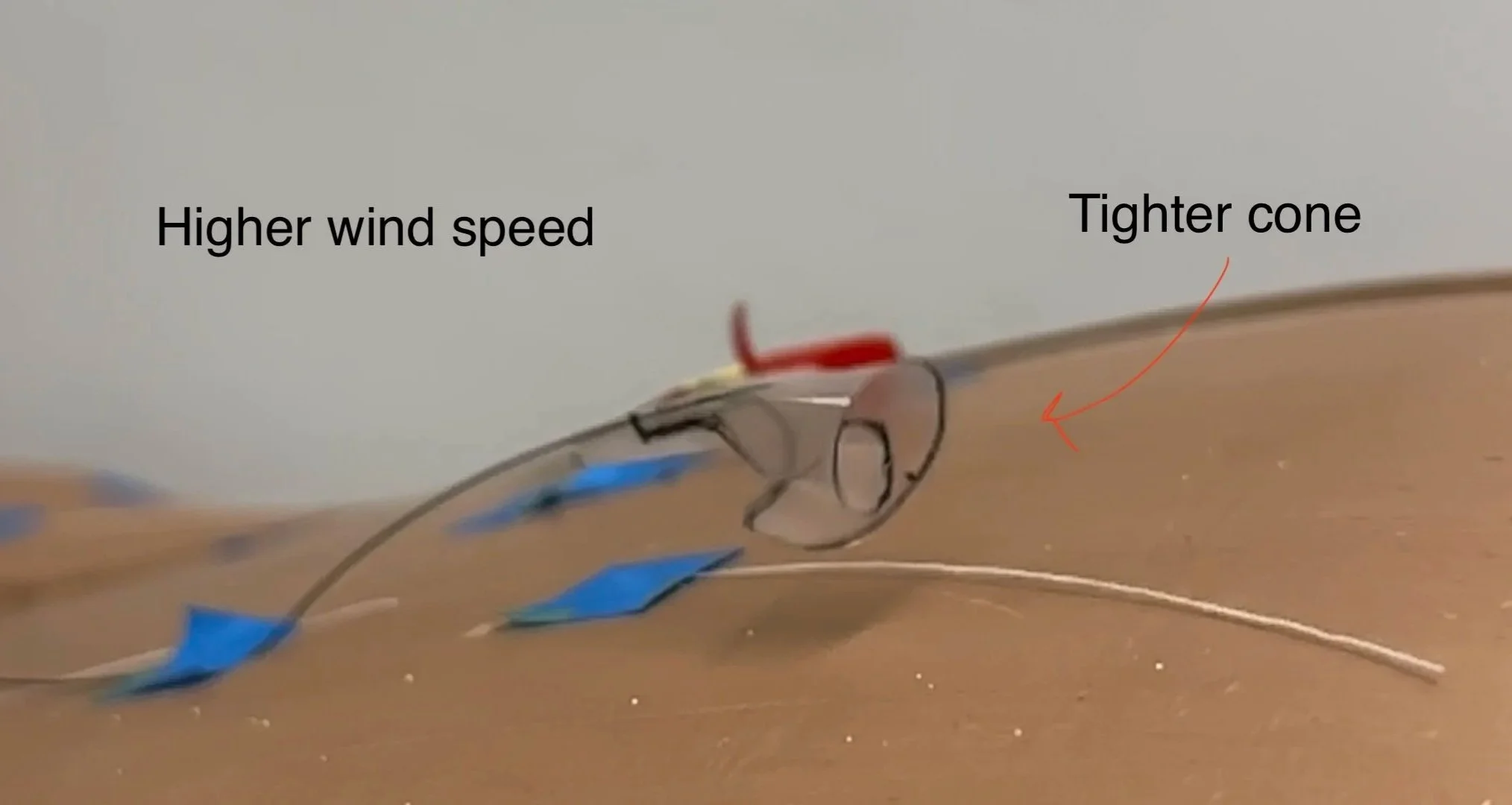

The ginkgo leaf naturally shifts from a broad, flat surface (ideal for capturing sunlight) to a tightly folded cone during strong winds. This behavior evolved to reduce drag on it’s branches.

Because the leaf’s form changes with varying wind speeds, it effectively acts as a natural air-speed indicator.

Material & Form Research

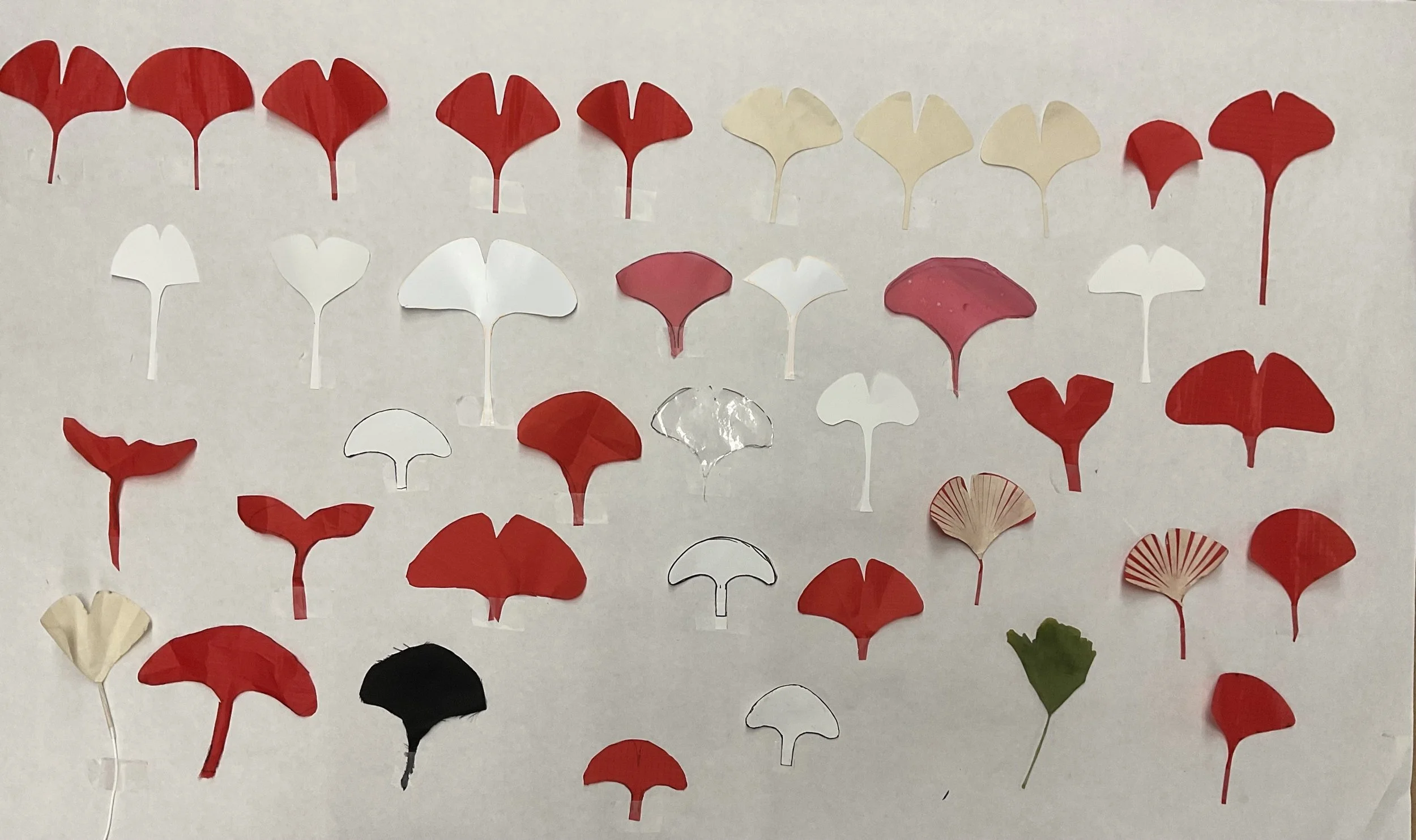

After multiple rounds of testing materials and forms, we discovered that ripstop nylon performed best, allowing the structure to cone in the wind without falling apart. The ginkgo leaf shape that produced the optimal coning effect emerged after testing over 50 prototype variations.

Improving the TUFT

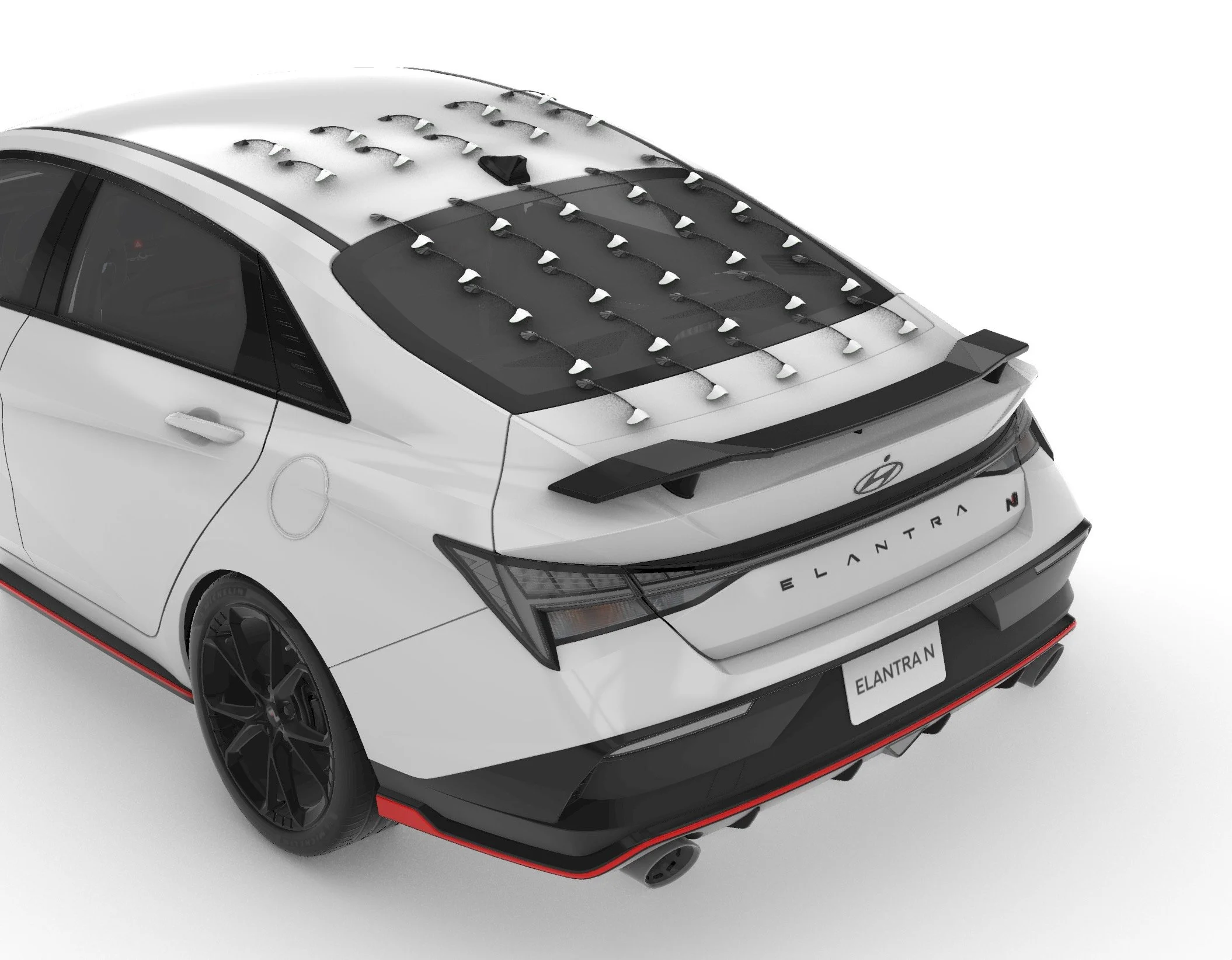

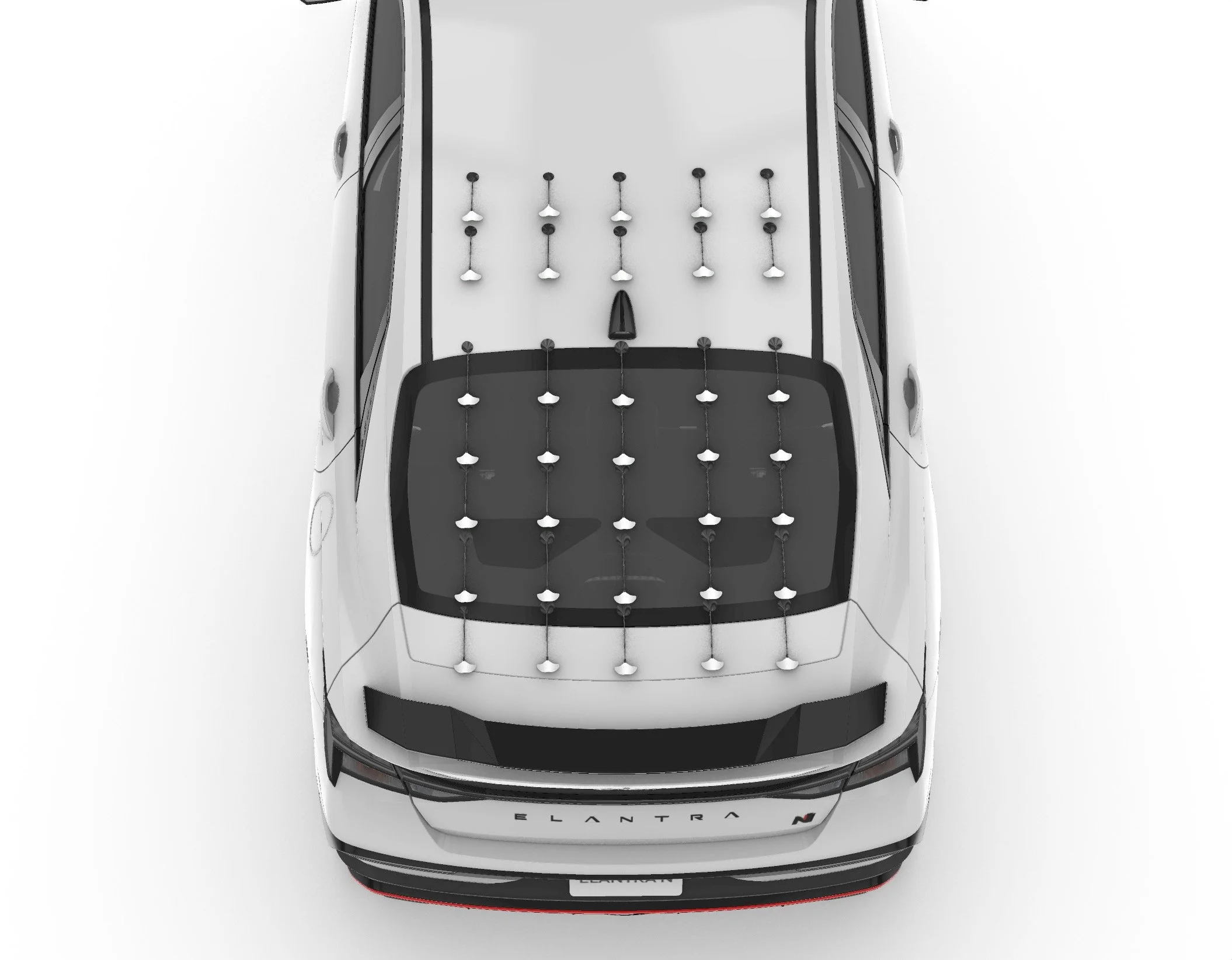

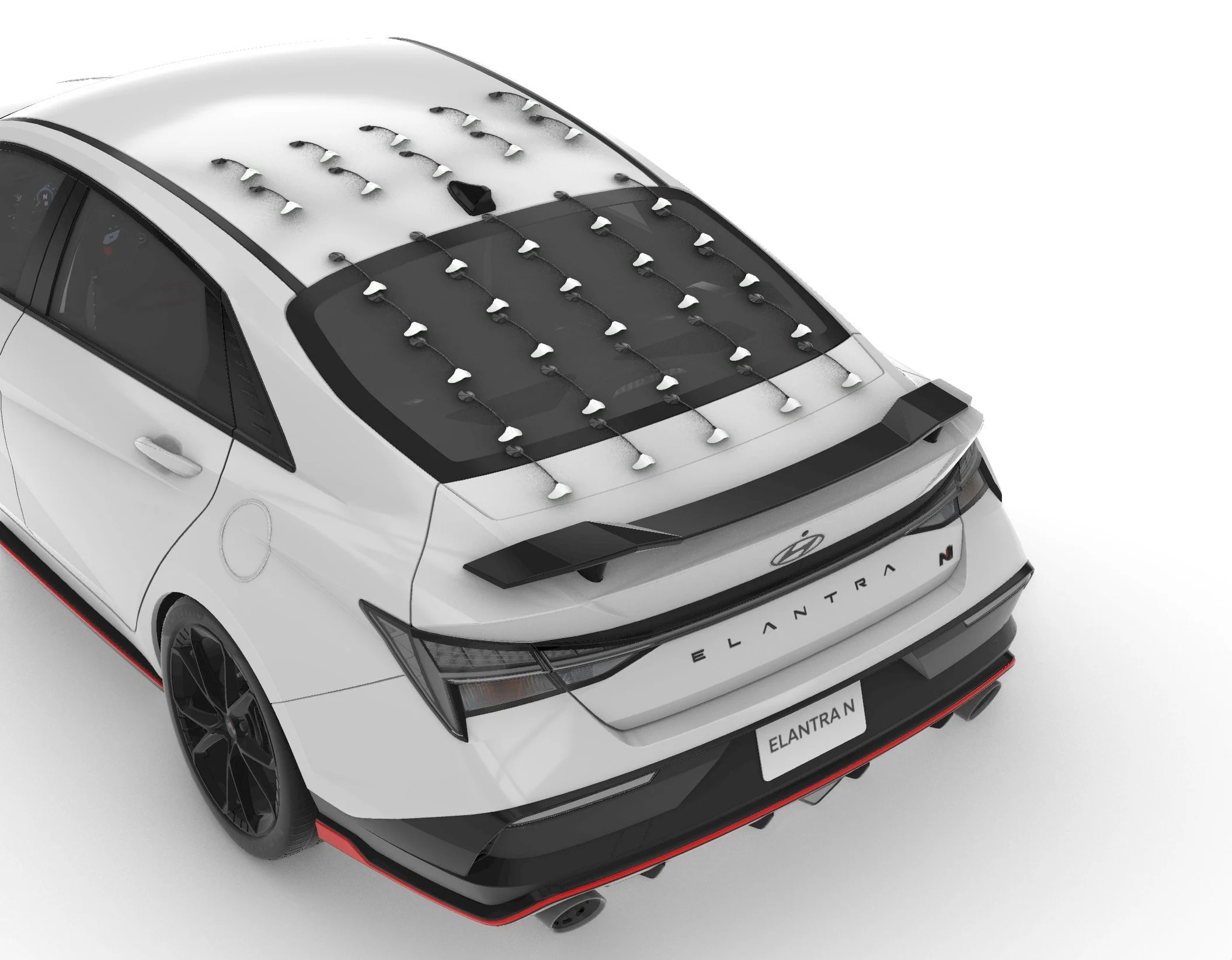

With a working prototype, we needed to determine which part of the vehicle would benefit most from our product. A car’s spoiler is designed to slow airflow ahead of it, generating downforce through increased drag. Our device visualizes changes in airflow velocity toward the rear of the vehicle, allowing us to demonstrate whether the spoiler is functioning effectively.

Final Car testing

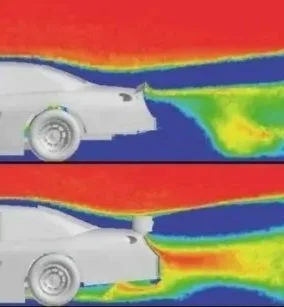

To test whether our concept worked, we built a spoiler for the back of a car and attached our prototypes to its surface. We then ran two tests at the same speed (30 mph) and observed how the cone changed shape. The results showed that the spoiler slowed the airflow in front of it, which was visible through the looser cone formation of our prototype.

Without spoiler 30mph

With spoiler 30mph